Choose the Stedox® method – and increase your profitability

SAVE ON REINFORCEMENT, CONCRETE, WORKING HOURS AND MONEY

Would you like to find out more? Book a 15-minute consultation and we will share tips on how you can start planning and building more profitable projects.

Choose the Stedox® method – and increase your profitability

SAVE ON REINFORCEMENT, CONCRETE, WORKING HOURS AND MONEY

Would you like to find out more? Book a 15-minute consultation and we will share tips on how you can start planning and building more profitable projects.

“The best invention for the concrete industry in 50 years,”

– Former President of the Concrete Association of Finland

Plan according to the Stedox method

Assemble elements twice as efficiently

Achieve greater profitability

Millimeter-precise height adjustment for a perfect end result

With the help of Stedox® assembly foot, you can set the elements to the precise height level by hand. Conctruction workers appreciate this feature since the elements are easily positioned within tolerances – and the end customers are satisfied.

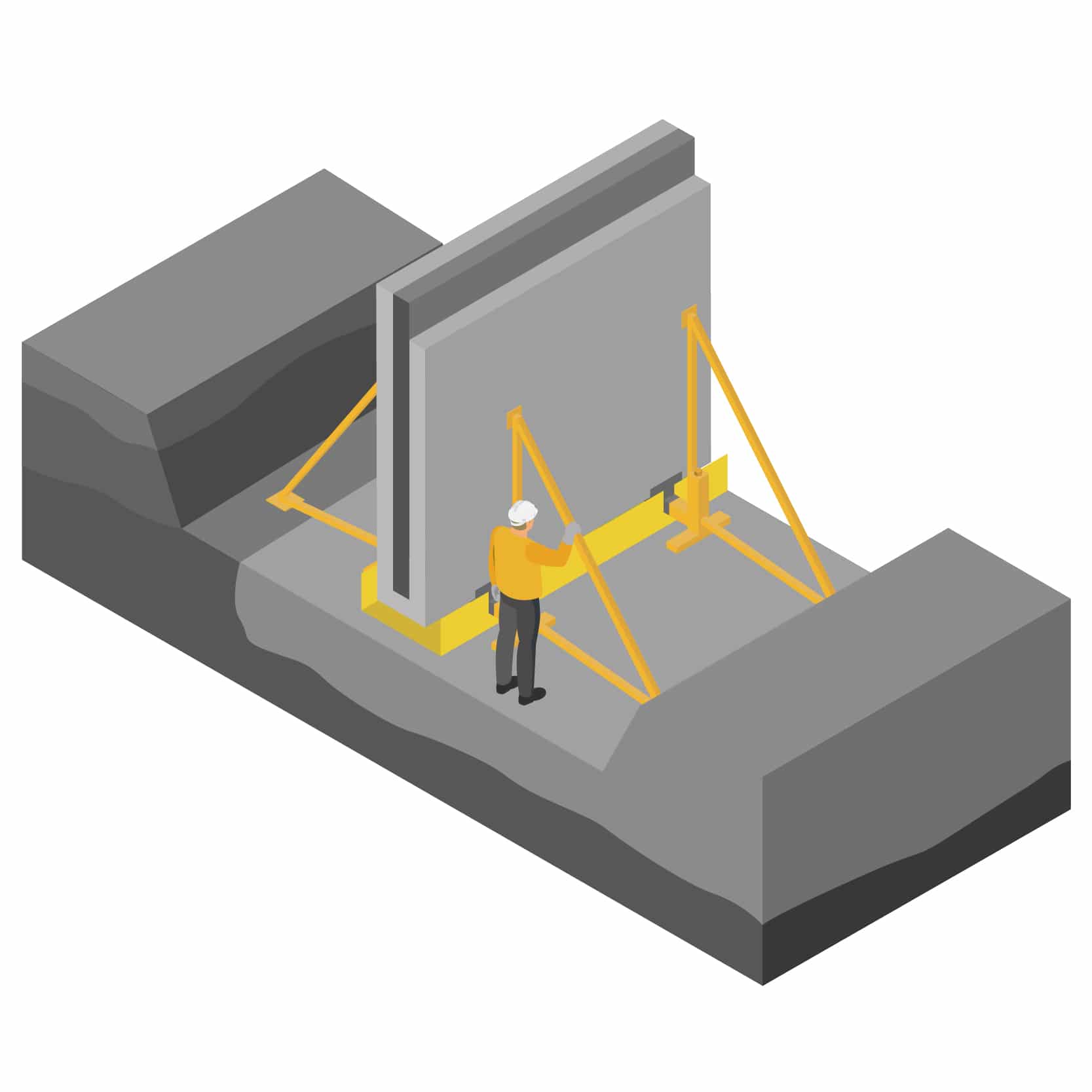

Safe and effective way to support the elements using innovative element supports

Stedox® innovative element supports allow you to assemble safely and efficiently without having to drill, bolt, or place out/cast concrete counterweights.

Installing concrete elements has never been as easy

The Stedox® assembly method was developed to save on labor and material costs.

Choose the Stedox® method – Save reinforcement, concrete, working hours and money

Book a 15-minute consultation and we will share tips on how you can start planning and building more profitable projects

Why choose the Stedox® method?

UP TO

%

FASTER CONSTRUCTION TIME

UP TO

%

LESS REINFORCEMENT AND CONCRETE

UP TO

%

LESS WORK STAGES

Watch videos from previous projects

Stedox® services always include

- Consultation when planning Stedox® projects

- Products needed for element assembly

- Expert support 24/7

- Fast delivery times

Choose the Stedox® method – and increase your profitability

SAVE ON REINFORCEMENT, CONCRETE, WORKING HOURS AND MONEY

Would you like to find out more? Book a 15-minute consultation and we will share tips on how you can start planning and building more profitable projects.

Choose the Stedox® method – and increase your profitability

SAVE ON REINFORCEMENT, CONCRETE, WORKING HOURS AND MONEY

Would you like to find out more? Book a 15-minute consultation and we will share tips on how you can start planning and building more profitable projects.